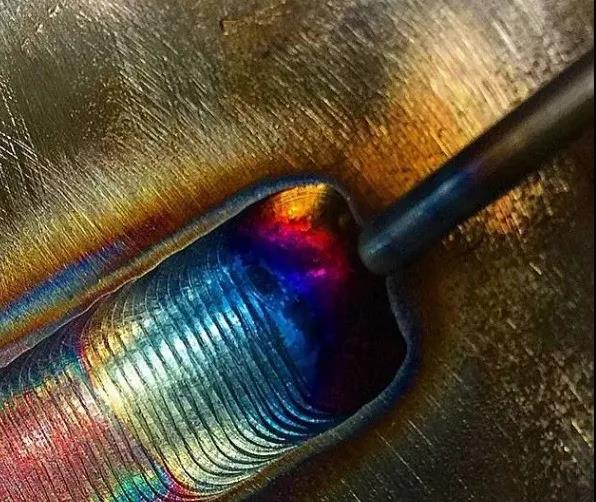

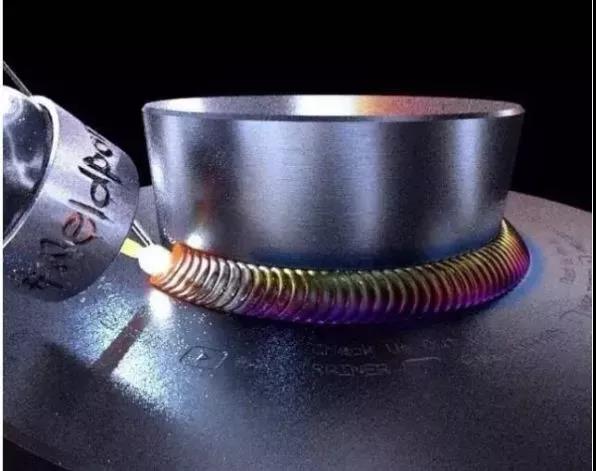

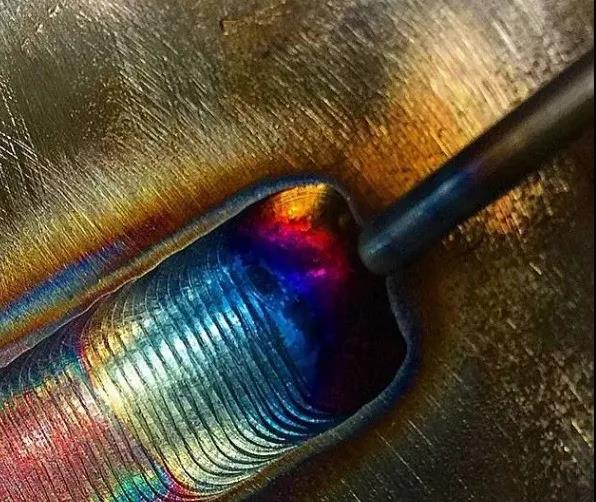

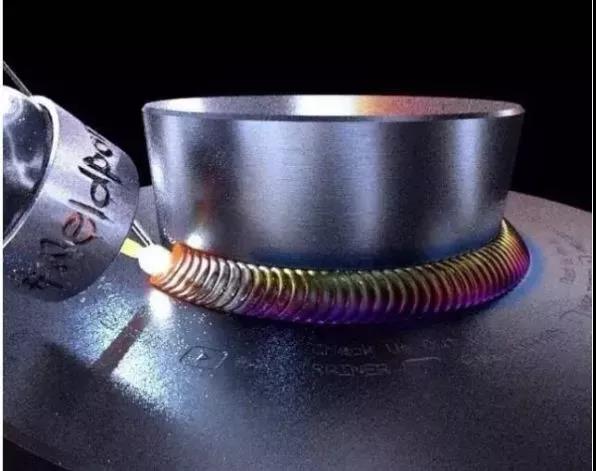

Fish scale welding

Summed up on the two words "steady, accurate".

"Stability""three stability"

1. The center of gravity

Welding is like martial arts, the first thing to do is the chassis to be stable, that is, "horse step" to be stable, not the center of gravity is not stable when shaking welding is difficult to weld a good weld.

2. The welding torch

Hand shake things can cause the formation of tungsten electrode burning molten pool the phenomenon of tungsten, weld edge is not neat, the scale size not neat, we can through the gun hand little finger and ring finger for stabilizing gun control, contact with the product can also be spread by argon arc welding of ceramic nozzle, abutting on the parts and then adjust the length of the tungsten electrode according to the depth of the crater is probably between 3 to 5 mm.

3. The wire feed stability

The method of wire feeding is adjusted according to the size of the weld groove. If the groove is small, the welding wire can be continuously fed in the center of the weld pool. When the width of the weld is large, the way of wire feeding is adopted.

"Accurate" "three accurate"

1. The parameters

Welding parameters are the key to the quality of welding, and it is very necessary to choose the correct welding parameters. Flat welding, vertical welding, according to the actual station, the actual plate thickness to choose the appropriate parameters and welding material specifications, welding current is small is not easy to arc, welding current is large is easy to weld through, molten iron next trip.

2. Accurate Angle and position

Welding gun Angle, welding position will affect the final welding molding, at the same time to avoid the emergence of welding defects (tungsten, no fusion, slag). General flat butt welding electrode swing method has zigzag, crescent, triangle, ring, and figure eight! The key of vertical fillet welding is how to control the molten pool metal. The electrode should swing up and down rhythmically according to the cooling condition of the molten pool metal.

3. time

In the welding process, when the first molten pool appears after arc initiation, the arc should be raised quickly. When the molten pool is instantly cooled into a dark red point, the arc is lowered to the arc pit, and the droplet falling overlaps with the molten pool in front by 2/3, and then the arc is raised. This rhythmically forms a fillet weld.

2021-12-31

2021-12-31