The installation and debugging of the prefabrication project of prefabricated pipes in the machine r

This project is a building mechanical and electrical pipeline prefabrication factory: it mainly provides prefabrication of prefabricated air conditioning room pipes. Users use BIM software to disassemble drawings and use our intelligent equipment to automate prefabrication. The quality is improved while the efficiency is 20 times that of traditional manual. The prefabricated pipe section can be transported to the project site and directly bolted for assembly.

The first phase of the project has provided the user with a set of prefabricated automatic welding center (4 sets of welding guns), a set of pipeline horizontal logistics transportation system and a set of pipeline light rail trolley transportation system.

The perfect logistics system solves the problem of limited space in the workshop of users (pipe raw materials into the workshop and finished pipe section out of the workshop are the same door).

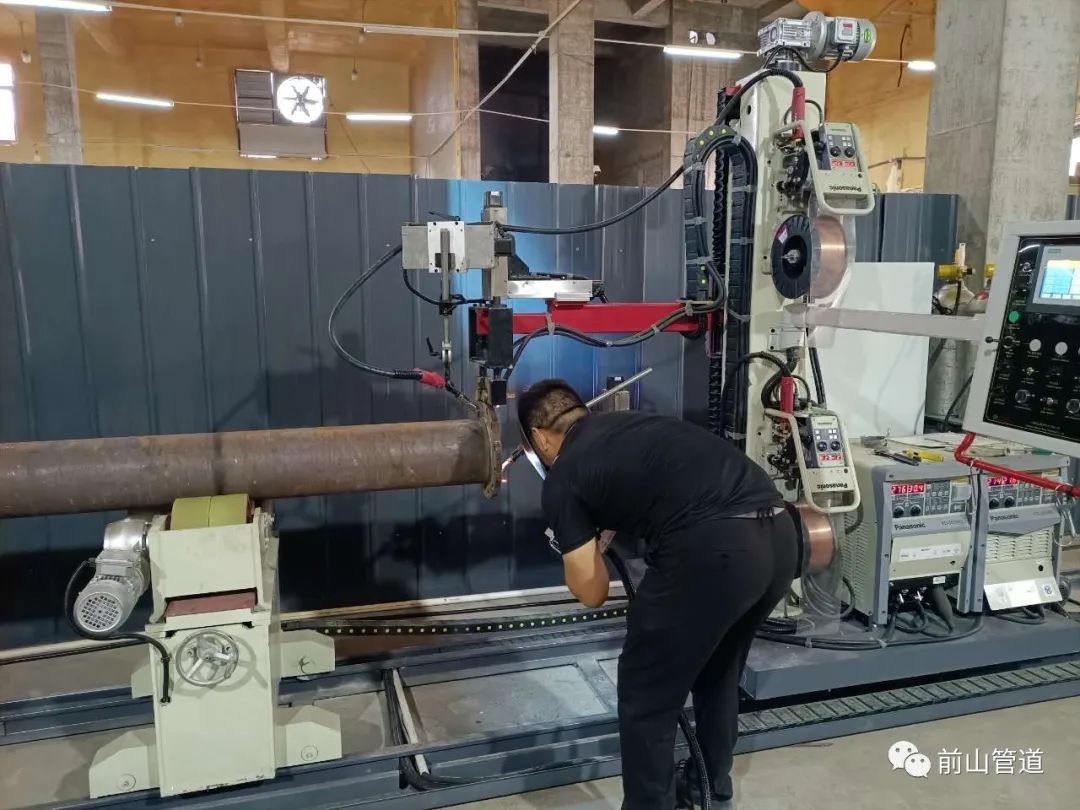

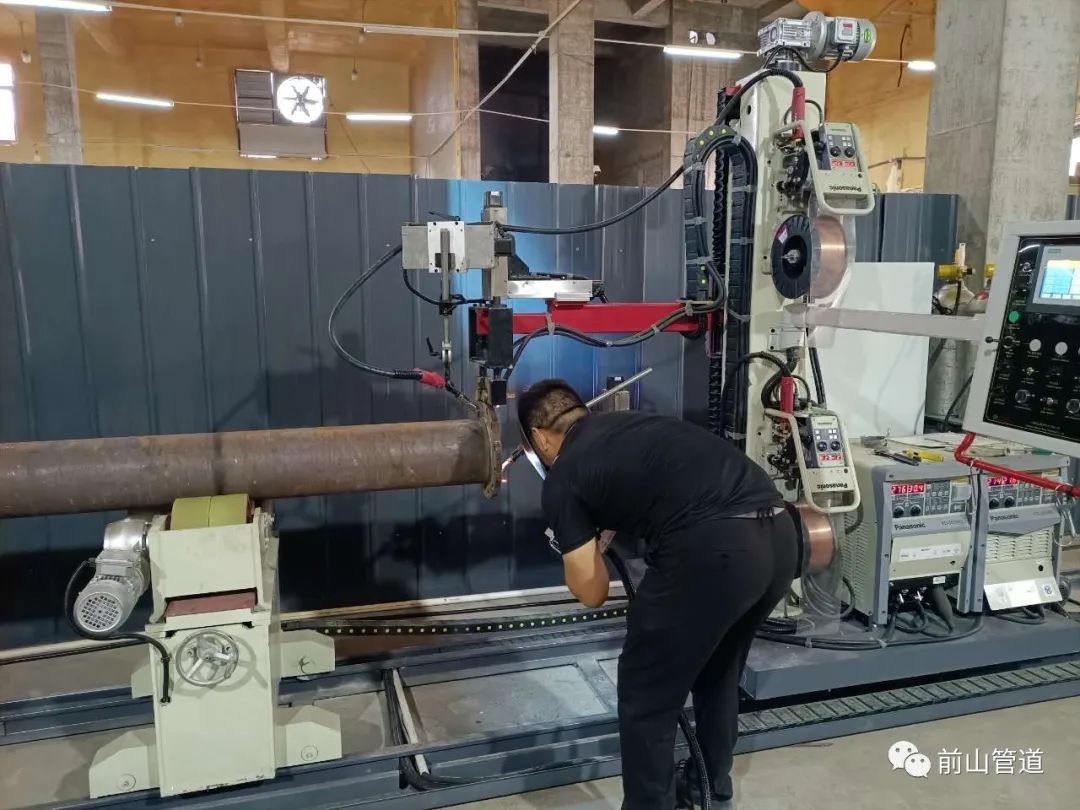

Pipe prefabrication automatic welding center

Applicable pipe length: 2-12m

Welding process: MIG gas welding process

Suitable material: carbon steel, stainless steel

Control system: PLC control

The fillet weld of the inserted flange can be automatically welded by two or four gas protected welding guns at the same time.

Applicable pipe diameter: DN50-600

Maximum load bearing capacity: 5000KGS

Track type: 18# light rail

Control transmission length: ≥1000MM

Horizontal transportation of pipes or pipe sections in groove machining or automatic welding process can be realized to reduce safety risks in lifting process.

Prefabricated construction of electromechanical engineering has become a general trend. Mechanized and automated pipeline prefabrication equipment can greatly improve the image of pipeline construction units and owners. The traditional construction mode is mostly "on-site processing and on-site installation mode", which mainly has the following disadvantages:

1, dry while measuring while changing, serious material waste;

2, high altitude work more, greater safety risks;

3. There are many welding operations and serious sound and light pollution;

4. Low construction efficiency and slow construction schedule.

The adoption of automated equipment for assembly construction has the following advantages:

1, greatly improve the quality of the project;

2, greatly reduce the site construction pollution;

3,greatly shorten the site construction period;

4, reduce the probability of safety accidents;

5, saving the processing site of the construction site;

6, reduce the unreasonable loss of engineering materials.

The traditional "huge crowd" tactics and manual methods have fallen behind. Mechanical replacement of manual has not only brought the improvement of quality and efficiency, but also brought significant progress in management, schedule control, image, standardization and cost saving. Especially for some overseas projects, this kind of promotion and progress will greatly improve the owner's good impression and trust to the construction side.

2022-06-10

2022-06-10