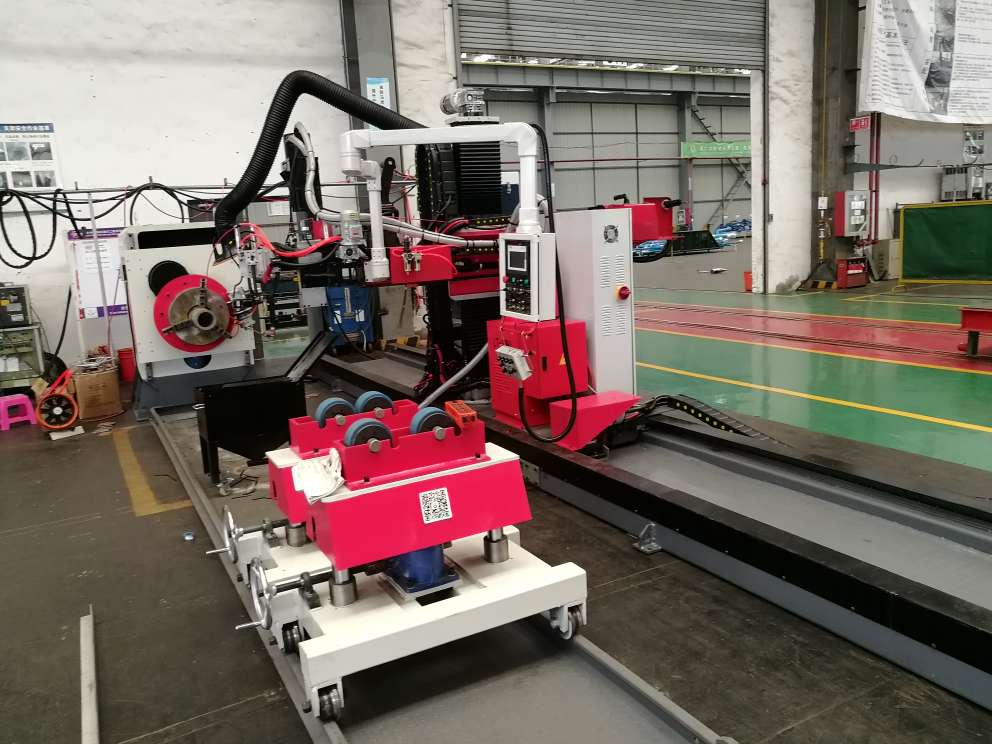

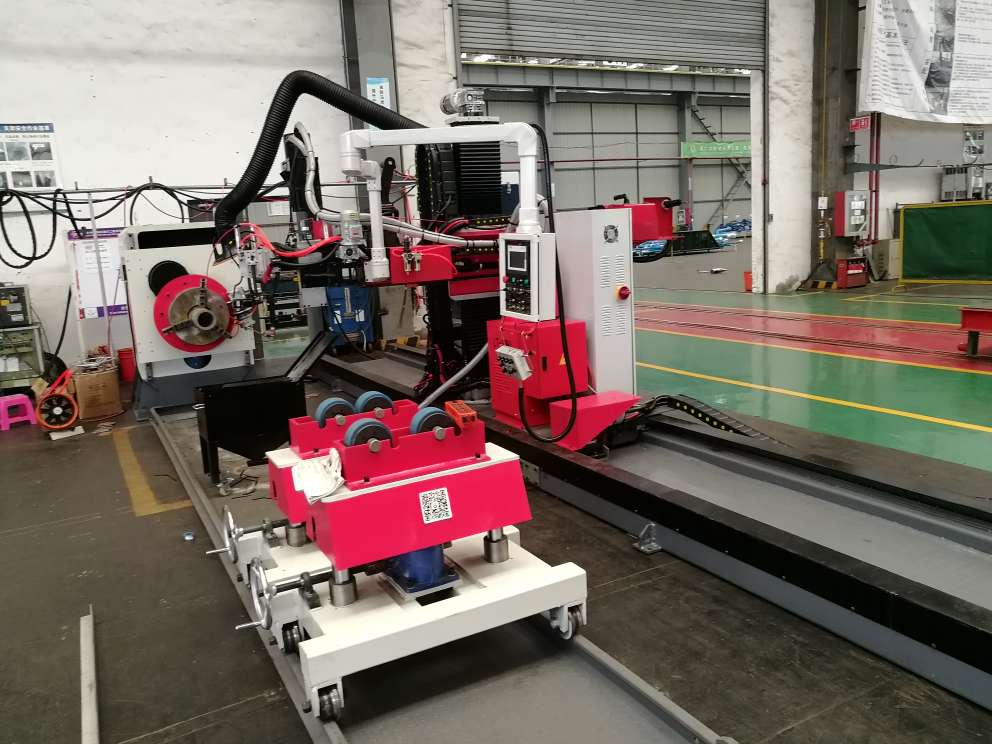

1.Use rail trolley conveying system to convey workpieces (pipe spools) to the position before the welding positioner; adjust the height of six jaw chuck on the welding positioner as per the central height of workpiece, after workpiece enters the jaw of six jaw chuck, the six jaw chuck tightens the workpiece; welding positioner uses clamp strength to realize uniform rotation of workpiece;

2.Welding torch is fixed on the trolley, welding trolley travels along the rail, moves the welding torch to proper position, and use adjusting mechanism to adjust the welding torch to accurate position. Use oscillation mechanism to realize oscillation of the welding torch, use the control cabinet and the control box to control the welding parameters, and use the following welding power to carry out automatic workpiece welding;

S.N. | Welding Method | Remarks |

1. | TIG argon arc welding | □ | 1 torch head |

2. | MIG gas shielded welding | □ | 1 torch head, including MAG 、FCAW |

3. | SAW submerged arc welding | □ | 1 torch head |

4. | TIG +MIG argon arc welding+ gas shielded welding | □ | 2 torch heads, including MAG 、FCAW |

5. | TIG +SAW argon arc welding+ submerged arc welding | □ | 2 torch heads |

6. | MIG +SAW gas shielded welding + submerged arc welding | □ | 3 torch heads |

7. | TIG +MIG +SAW argon arc welding+ gas shielded welding + submerged arc welding | ■ | 3 torch heads, including MAG 、FCAW |

Note: ■ Welding power stipulated in the Contract, □ Other optional welding powers

|

2022-12-30

2022-12-30