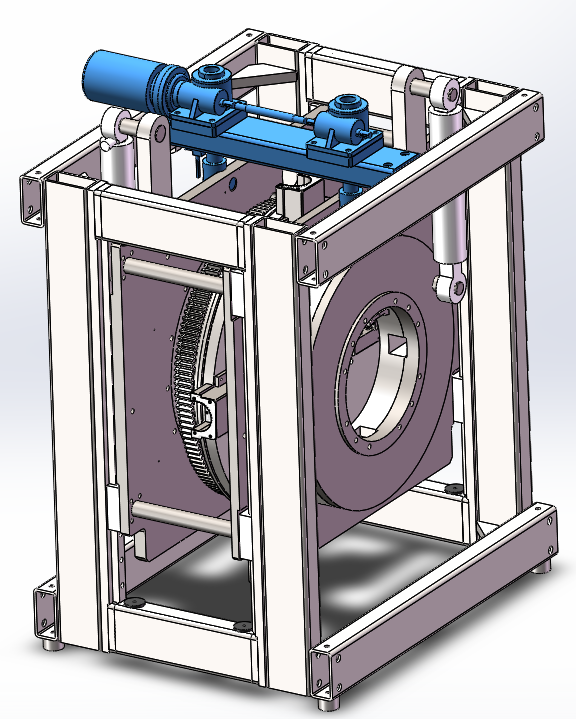

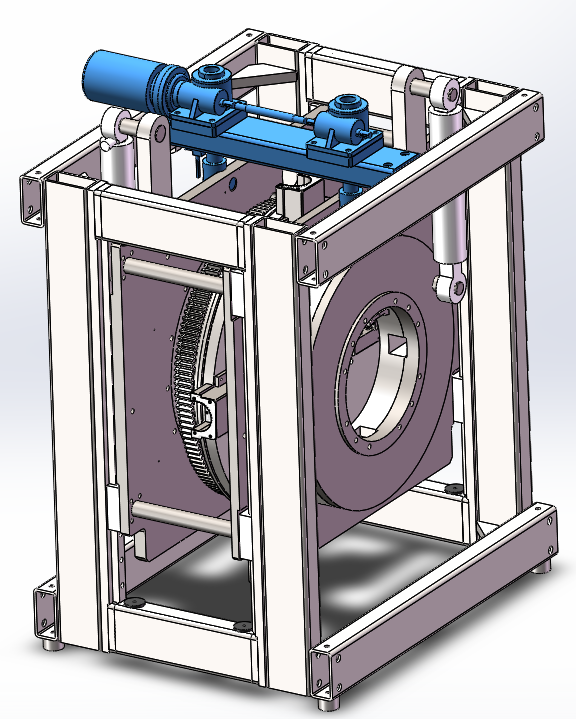

Pipe beveling machine is a special tool for pipe or plate to carry out chamfering beveling on the front end face of welding. It solves the shortcomings of flame cutting, polishing machine grinding and other operation processes such as Angle is not standardized, slope is rough, work noise and so on. It has the advantages of simple operation, Angle standard, smooth surface and so on. Below is our pipe beveling machine.

When the pipe is transported to the required cutting position through the feed roller of bevelling machine and the discharge roller of bevelling machine, it touches the contact and origin photoelectric electricity on the pusher of the fixed length system, so as to stop the pipe conveying to achieve precise length determination; Then start the beveling machine to complete the fixed length of the pipe cutting groove. After the beeping machine is cut off, the fixed length system will automatically measure the required length of the tube driven forward by the trolley to achieve the fixed length cutting of another length of pipe. The fixed length system adopts absolute coordinates, and sets the origin and positive and negative directions of coordinates when debugging the machine tool. The fixed length of consecutive sections can be realized only by changing the length in the touch screen.

2023-02-17

2023-02-17