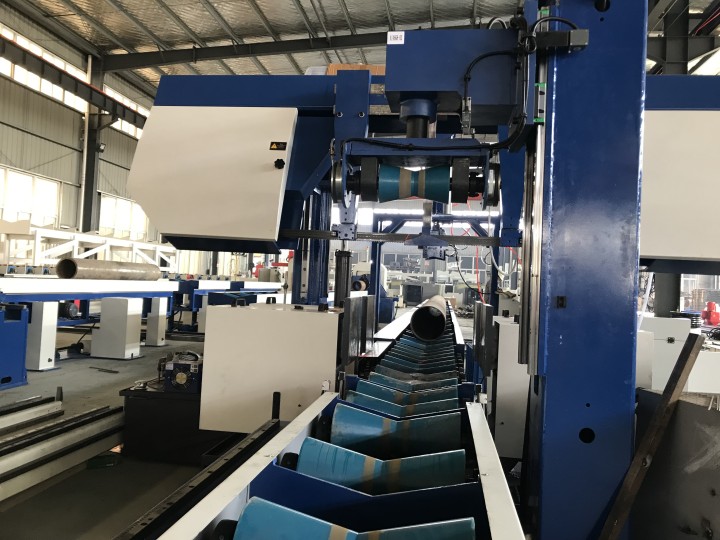

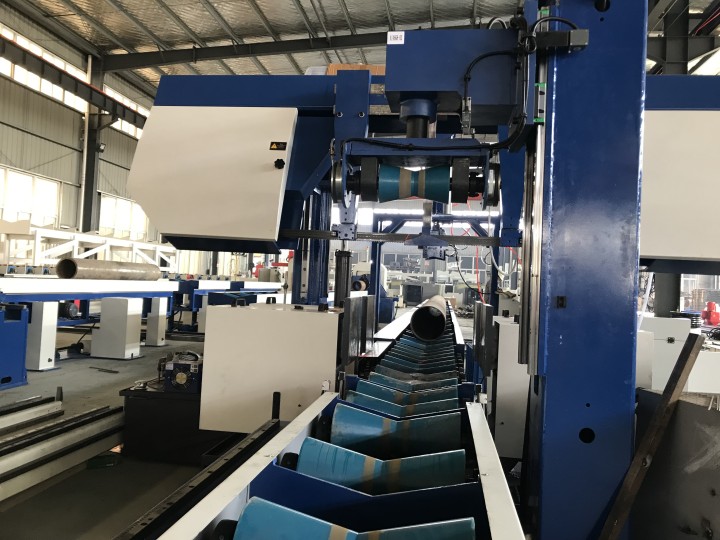

CNQG/450 automatic Nesting Pipe Cutting Machine is a new generation of automatic pipe cutting machine introduced by our company and developed and produced by ourselves with international advanced technology.

n Model No. : CNQG/450 automatic nesting pipe cutting machine

n suitable pipe specification:: ½″~2.5″ 6M length

n Power:10KW

n Dimensions: 10m length * 2.2m width * 1.7 height

n Processing efficiency: according to different pipe diameters, normally one can be processed in about 3 to 5 seconds

the production line consists of material storage platform, feeding mechanism, sort material mechanism, hydraulic clamping mechanism, main shaft power mechanism, servo threading feeding mechanism and so on. Through dynamic analysis and finite element analysis of the machine tool, each mechanism makes its geometric structure more reasonable, and the proper collocation of the reinforcement ensures the high rigidity of the foundation parts.

Using industrial control computer and Mitsubishi PLC system intelligent control, according to the cutting list automatically calculate the length of the cutting pipe.The feeding mechanism is controlled by servomotor to meet the needs of different pipe lengths and ensure machining accuracy

C3 high precision and high strength ball screw is adopted.Adopt high-precision locking nut, ball screw after pre-stretching, greatly increase the rigidity of transmission and eliminate the influence of thermal deformation during movement, thus ensuring the positioning accuracy and repeated positioning accuracy of machine tool.

The main shaft feed adopts the design of heavy load linear slide rail support, the slide seat of the line rail is widened, the roller heavy load line rail can meet the requirements of fast speed and high precision, and can also be strong cutting, but also increase the service life of the guide rail and other characteristics of the machine tool.

The machine tool is equipped with sealed protective cover, which can effectively protect the guide rail and lead screw and extend its service life.

The whole frame can be lifted and lowered automatically to meet the requirements of different pipe diameters.

The wiring in the electric cabinet conforms to the national electrical safety code to ensure the operation of the control system without external interference. Better ensure production safety.

2023-04-14

2023-04-14