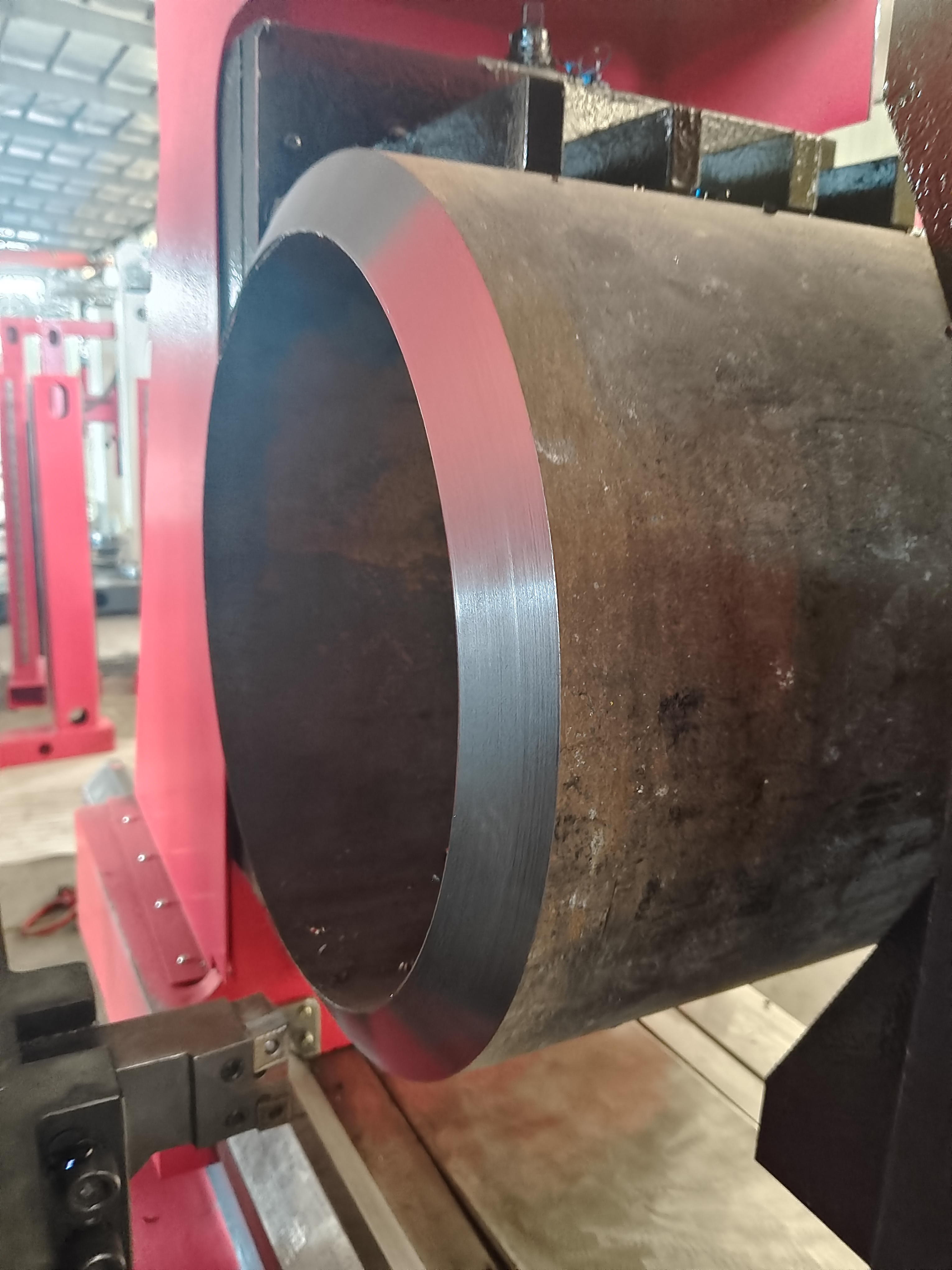

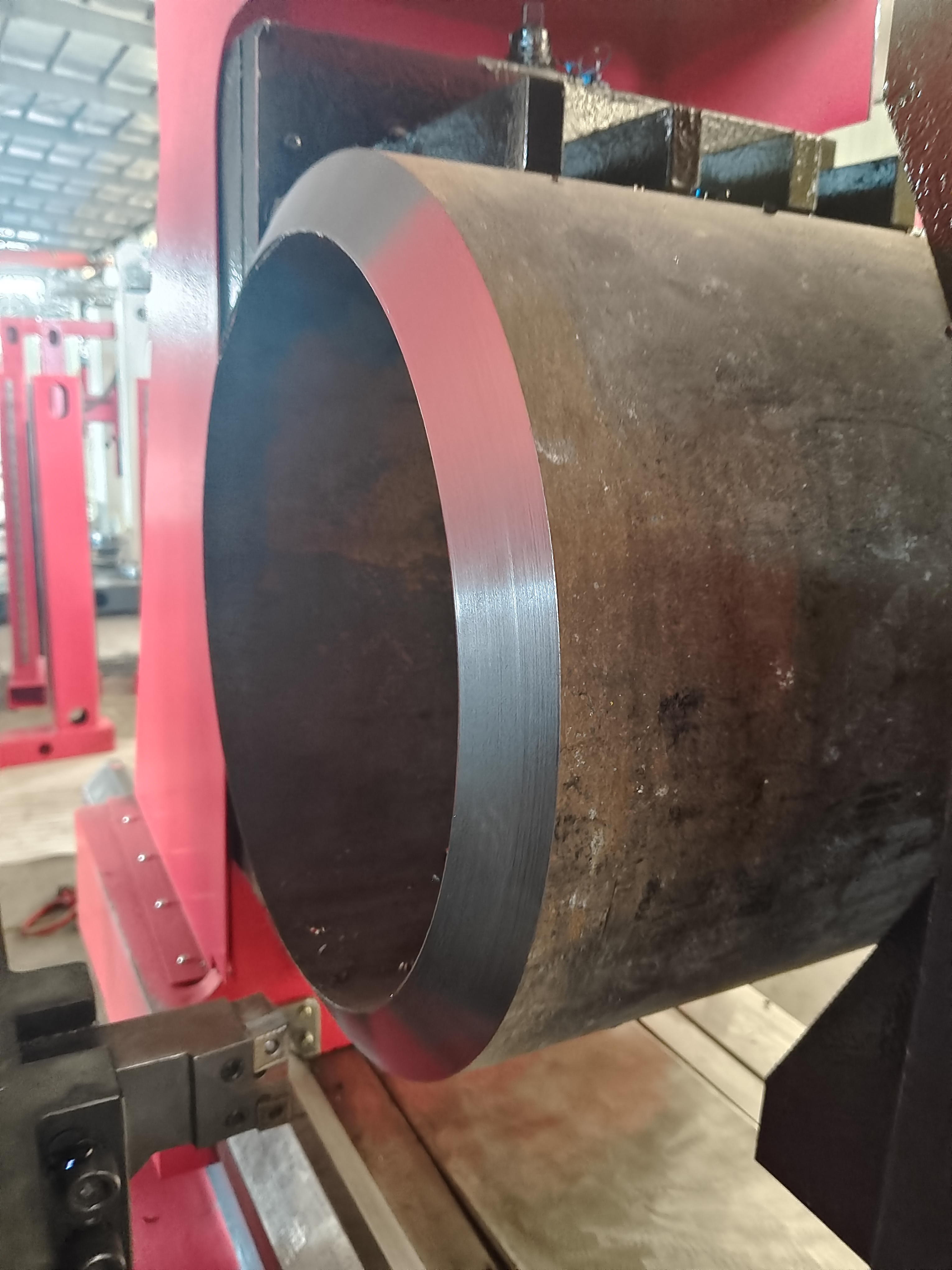

CNC pipe cutting machine is a type of CNC automation machine specifically used for cutting metal pipes, such as steel pipes, copper pipes, stainless steel pipes, etc.

It adopts a high-precision CNC system that can accurately control the length and angle of cutting, with high cutting accuracy, fast cutting speed, and simple and convenient operation.

CNC pipe cutting machines are widely used in industries such as mechanical manufacturing, petrochemicals, pipeline installation, metal structures, and shipbuilding.

It can accurately cut various shapes and sizes of metal pipes according to requirements, improving production efficiency and reducing costs, making it an ideal choice for cutting metal pipes.

In addition to high precision and fast cutting, CNC pipe cutting machines also have the characteristics of easy operation and maintenance, making it easy for even beginners to get started.

It is equipped with an intelligent control system that can automatically adjust the cutting speed, feed rate, and cutting depth, ensuring the stability and safety of the cutting process.

In addition, CNC pipe cutting machines have a wide range of applicability and can cut pipes of different materials and thicknesses, meeting the needs of different industries and customers.

With the continuous development of the manufacturing industry, the application scope of CNC pipe cutting machines is also constantly expanding.

In addition to traditional metal pipe cutting, CNC pipe cutting machines can also be used to cut plastic pipes, composite material pipes, etc.

The emergence of these new materials provides a broader application space for CNC pipe cutting machines.

Overall, CNC pipe cutting machine is an efficient, accurate, safe, and easy-to-use metal pipe cutting equipment, which is one of the indispensable equipment in the manufacturing industry.

Its emergence not only improves production efficiency and reduces costs, but also brings more innovation and possibilities to the manufacturing industry.

In addition to the above advantages, CNC pipe cutting machines also have many other features and advantages.

Firstly, it has high flexibility and adaptability, and can be customized and adjusted according to different cutting needs to meet the personalized needs of customers.

Secondly, the CNC pipe cutting machine has high cutting quality, with flat cuts, no burrs, and no deformation, which can ensure the quality and accuracy of the product.

In addition, the cutting accuracy and stability of CNC pipe cutting machines have been widely recognized, providing customers with reliable products and services.

In the future development, the CNC pipe cutting machine industry is facing many opportunities and challenges.

With the transformation and upgrading of the manufacturing industry and the improvement of intelligence level, the application field of CNC pipe cutting machines will continue to expand.At the same time,it is also necessary to continuously research and introduce new technologies and processes to improve the quality and performance of products,

in order to meet higher customer requirements.

2024-04-26

2024-04-26