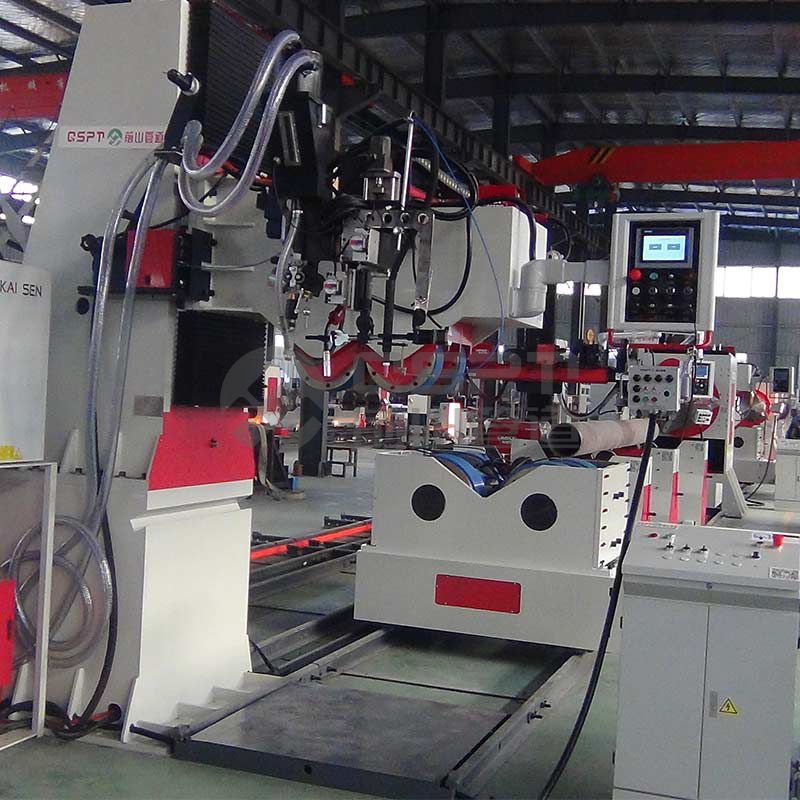

Pipe Fabrication Automatic Welding Center(Chuck + Rotator)

First single- or three-phase power Millermatic that welds

material from 22 gauge to 1/2 in thick in a single pass. Perfect for fabrication, manufacturing, maintenance and repair.

Inquire Now

Advantage:

Performance features: Integrated product; overcome the drawbacks of cantilever welding machine and regular welding machine; suitable for welding spool piece such as "fitting + pipe + fitting" ; the welding efficiency increased by more than 100%; one fixed type welding positioner with chuck; one Split Type Pipe Automatic Welding Machine; one cantilever welding trolley; three movable supporting trolleys; two 18# light track; the positioned and automatic welding machine installed at both ends of rail; standard configuration:one or two Lincoln Flextech650 multi-function welding power; TIG/MIG root welding with QSPT's root welding technology; TIG/MIG/SAW fill-in and cap welding; operated with an aluminum alloy wire control box

The perfect combination of split and cantilever welding machines

Simutaneous welding of two weld joints on a long pipe spool

Heavy duty chuck, super torque: 13200 N.m

Standard configuration: Lincoln Flextech650

TIG/MIG/ SAW

MAX. DN1200

MAX. 60mm

MAX. 800DI/D(MIG+SAW)

Message: