Advantage:

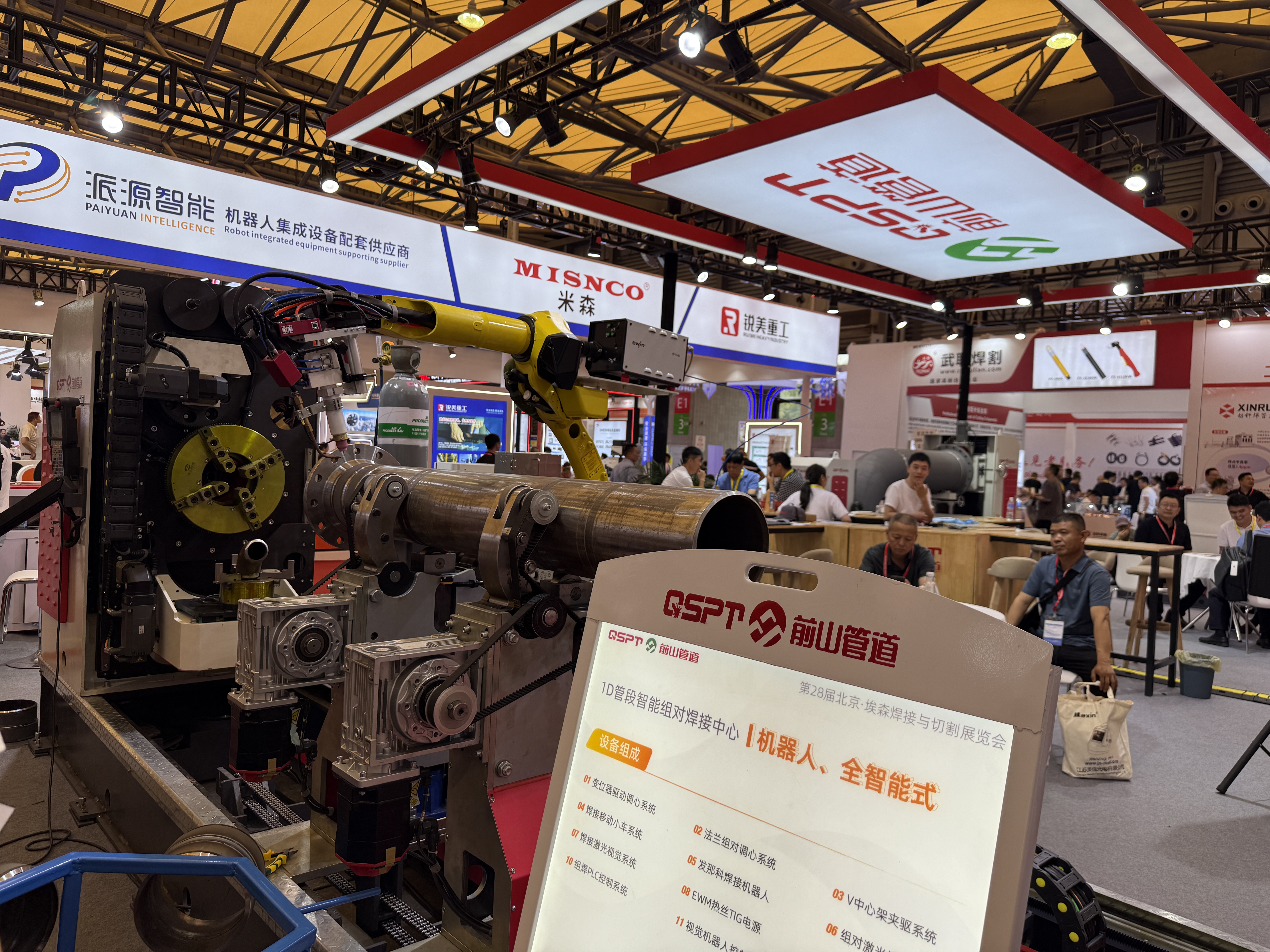

Intelligent Fitting-up and Welding Center for Pipe Sections

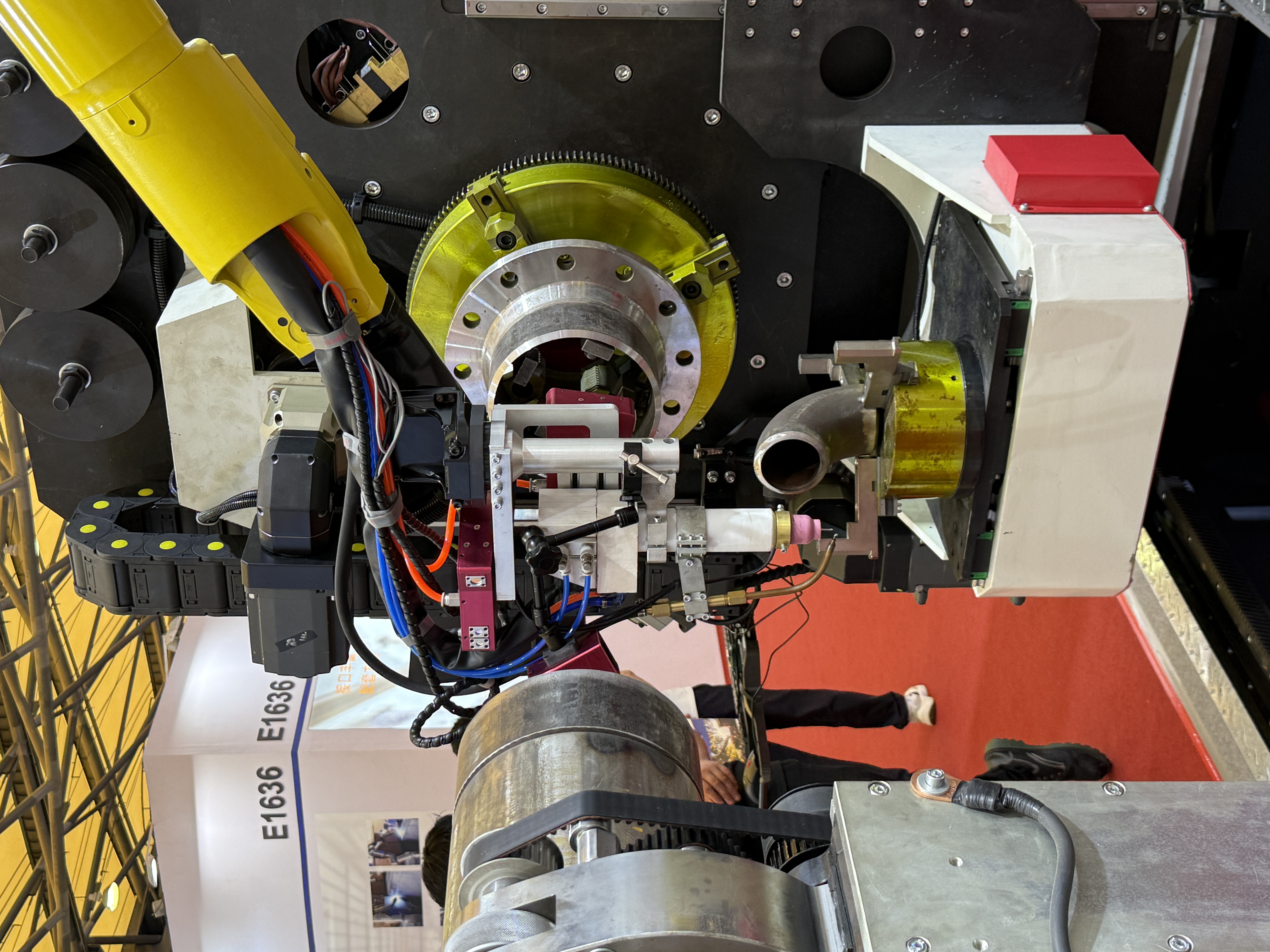

This integrated system automates precision fitting-up and adaptive welding of pipe sections (straight pipes, elbows, tees), tailored for oil & gas, shipbuilding, and energy sectors.

Core Capabilities

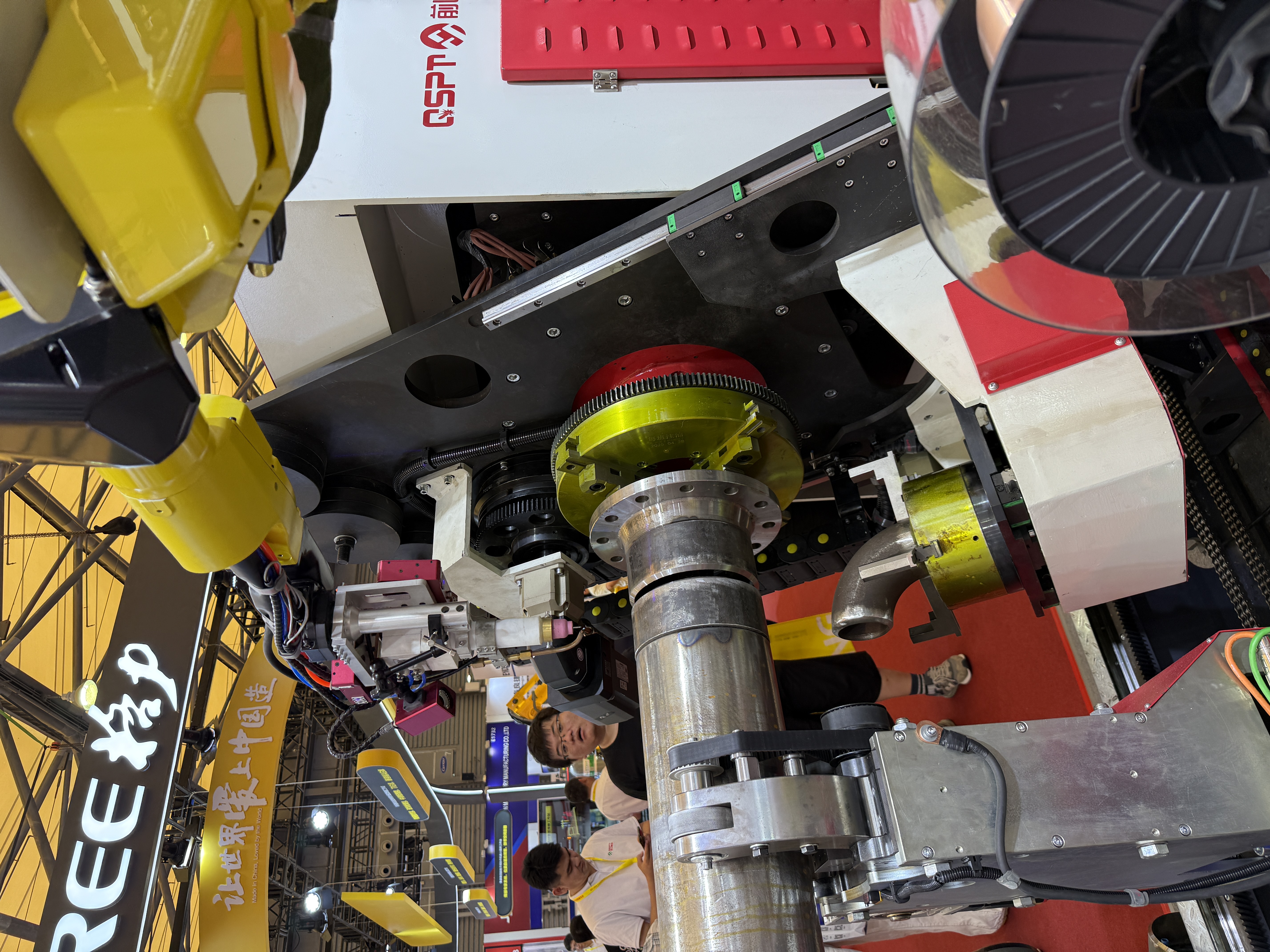

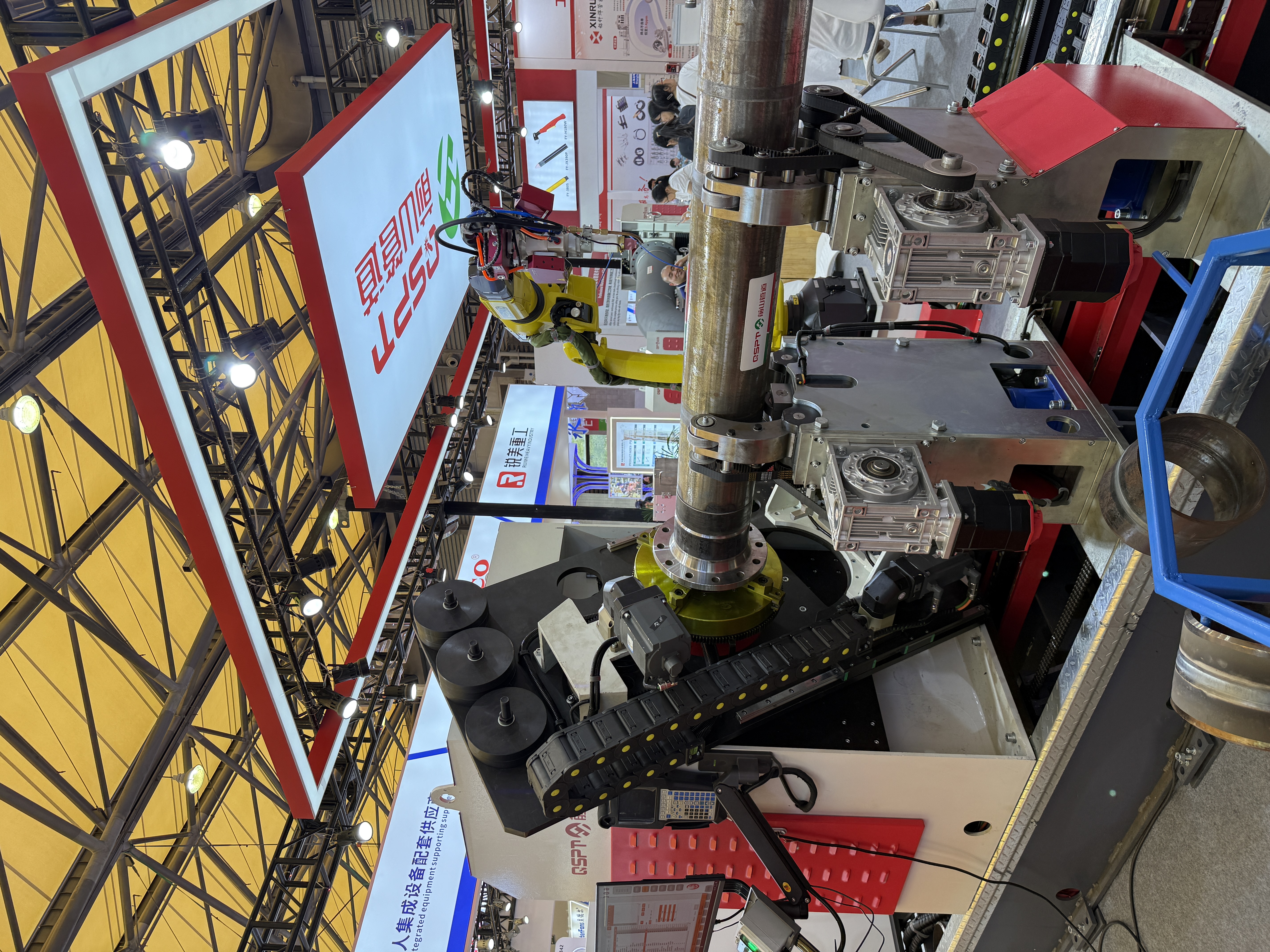

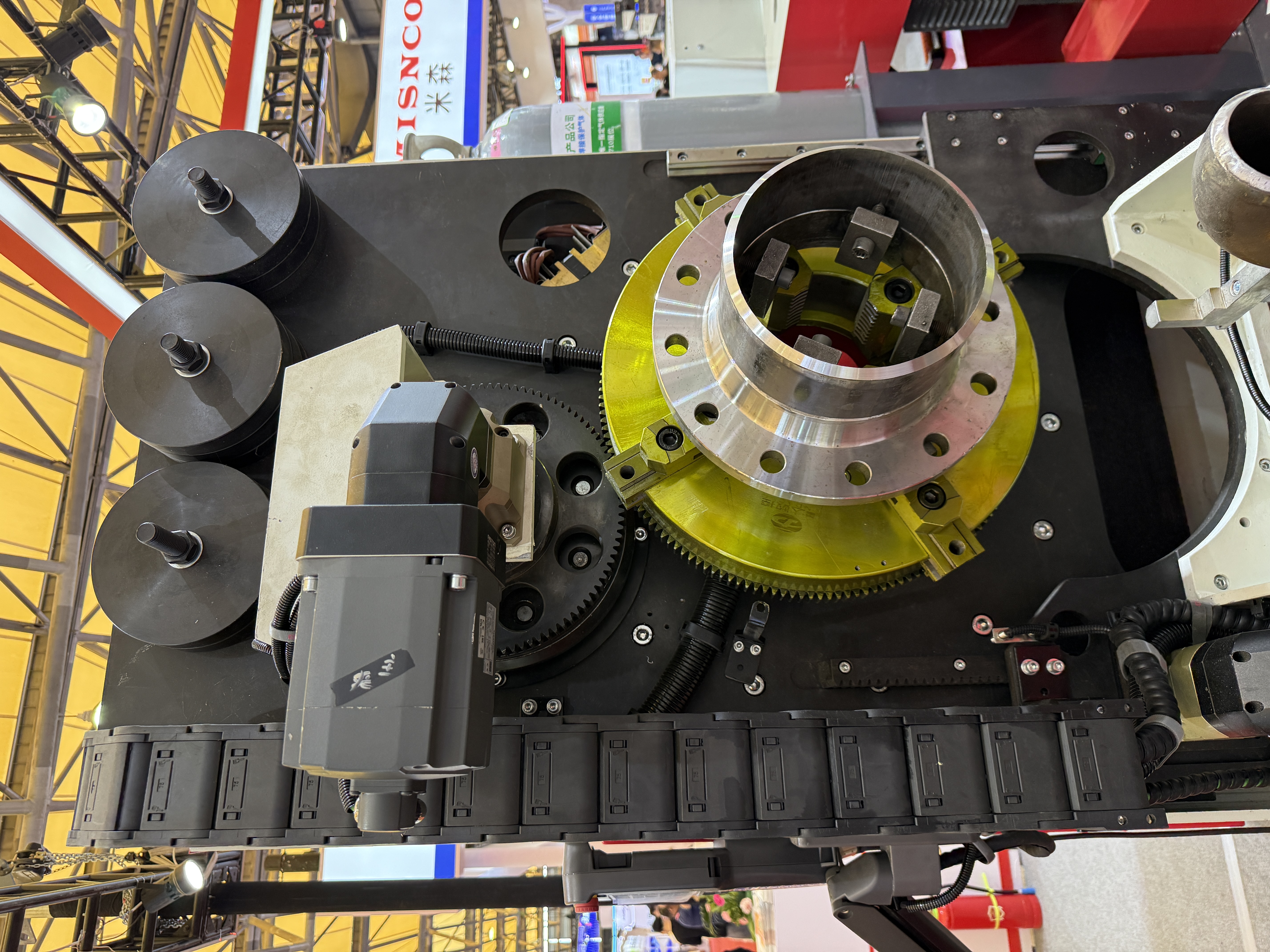

1.Intelligent Fitting-up System

3D laser scanning measures pipe geometry (diameter, ovality, bevel angle) to generate optimal alignment paths.

6-axis servo clamps correct misalignment, gaps, and angular offsets

Force feedback control prevents deformation during clamping.

2.Adaptive Welding System

Robotic arms with TIG/MAG torches handle single/multi-pass welding.

Intelligent process control features:

│ - Vision tracking: Real-time seam tracking with trajectory compensation

│ - Arc monitoring: Defect detection (porosity, lack of fusion) via voltage/current analysis

│ - Thermal management: Closed-loop interpass temperature control.

Value Proposition

Efficiency: 80% less fitting-up labor, 3x faster welding.

Quality: ≥99% RT/UT pass rate by eliminating human errors.

Cost: 40% less material waste, 25% energy reduction.

Message: